Founded in 1997, Nazhan Gıda İç ve Dış Tic. Ltd. Şti. has become a leading name in the lozenge industry by combining innovation, technology, and an unwavering commitment to quality. From its modest beginnings in a 500 m² facility, the company has expanded to a modern 1,500 m² production plant, continuously investing in customer satisfaction and technological excellence.

By integrating steam cooking and vacuum spray systems, Nazhan Gıda has redefined lozenge production standards. This advanced method—developed in collaboration with TÜBİTAK and Selçuk University—enables the production of lozenges with a glassy texture, extended shelf life, and enhanced preservation of natural ingredients.

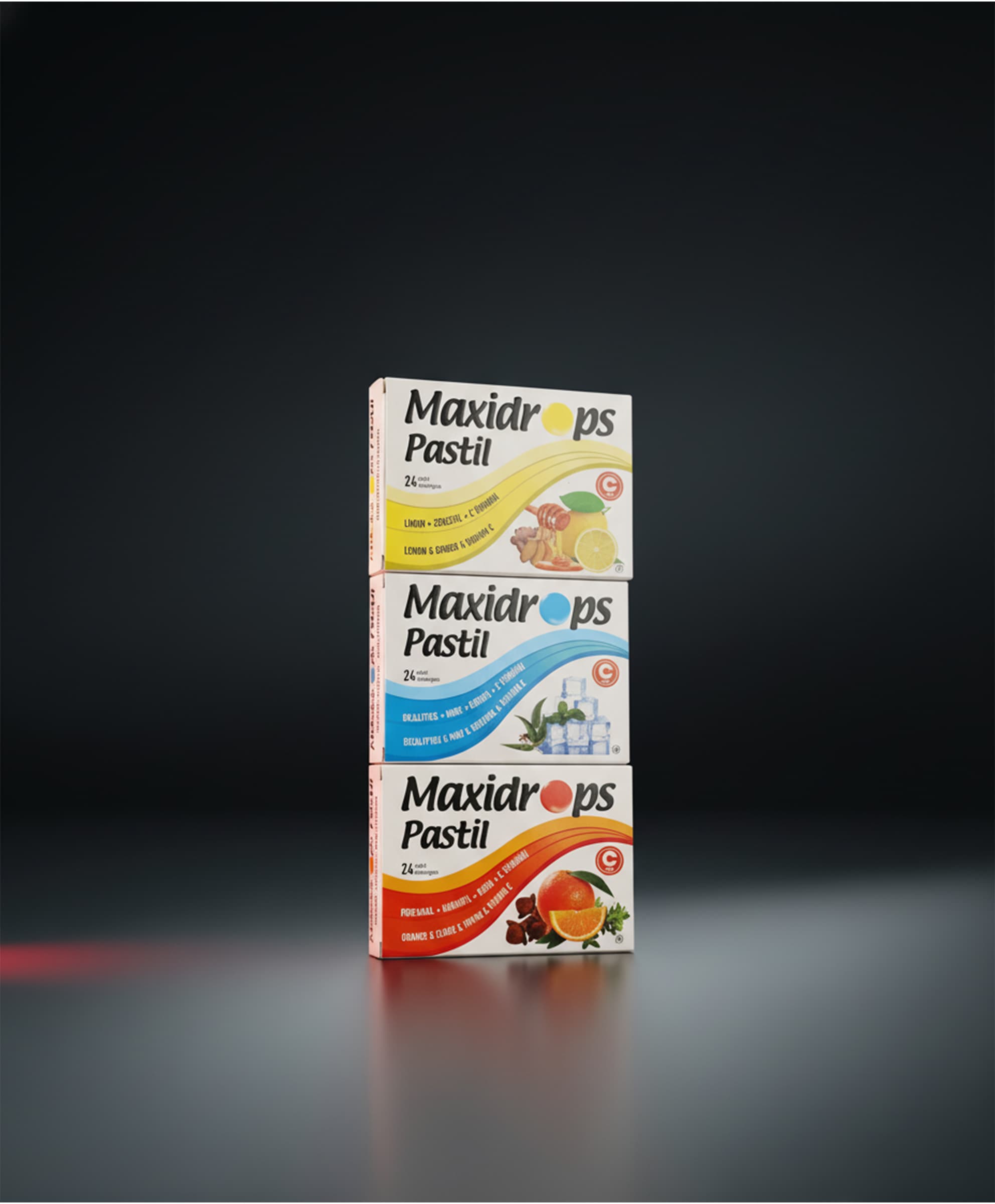

In 2010, the company began contract lozenge manufacturing, and in 2014, it launched its own brand, MAXIDROPS, marking a milestone in its corporate journey. Today, Nazhan Gıda produces sugar-free lozenges, dextrose tablets, and herbal tea tablets under GMP-certified cleanroom conditions, ensuring maximum hygiene and quality.

With an annual capacity of 6 million boxes of lozenges and 1.25 million boxes of tablets, Nazhan Gıda stands among Turkey’s top producers. All manufacturing processes comply with ISO 22000:2005 (Food Safety Management) and ISO 9001:2008 (Quality Management) standards.

Thanks to its dedication to excellence, Maxidrops currently exports to 2 countries and has signed export agreements with 10 more, strengthening its global presence. With a perfect balance of tradition and innovation, Nazhan Gıda continues to proudly represent Turkish craftsmanship and quality in international markets.

Throat Lozenges

Throat Lozenges

Capsule Filling

Capsule Filling

Tablet Production

Tablet Production

Lozenge Production

Lozenge Production

Effervescent Tablet Tea Production

Effervescent Tablet Tea Production